Teach In

To create a dispensing program the user drives with the integrated head camera to the actual position. Standard elements like dots, lines, curves and circles are available. Time-consuming pattern like for example meandering shapes on surfaces are possible by prepared forms. The virtual display of the camera image enables the exact alignment of the dispensing on workpiece or PCB. Therefore times of programming and runs for testing are shortened.

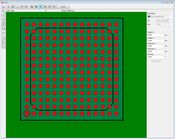

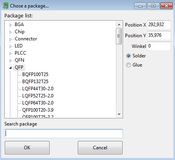

Gerber data conversion

Common Gerber files are used to create dispensing points using template thickness and SMD pad information. Dot size, size and shape are easy to set and optimize for each component and pad on the board.

![[Translate to Englisch:] Dxf-Datenkonvertierung](/fileadmin/_processed_/a/f/csm_Dxf_datenkonvertierung_0a605857a9.jpg)